Hydraulics of duckbill valve jets

Investigators:

- Prof. Joseph Hun-wei Lee

- Dr. H.W. Tang

- Mr. Jaydeep Karandikar

- Ms. L. Li

¡@

Introduction

¡@

|

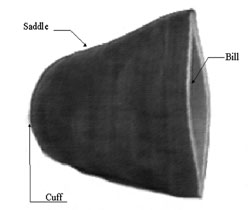

Duckbill-shaped rubber check valves are often installed on wastewater effluent diffusion systems and stormwater outfalls. A duckbill valve is essentially a flow sensitive variable-are valve. At no flow condition, the flaps of the valve remain closed. As the flowrate increases, pressure is exerted on the flaps of the valve, and the valve opens more, Duckbill valves differ from conventional fixed-diameter round ports significantly: I) the valve jet velocity varies nonlinearly with the flowrate; reasonably high velocities can be maintained even at very small flowrates; ii) the head-discharge relation is however approximately linear. These valves can prevent sea water sediment, and aquatic life from entering the outfall, and achieve optimal mixing of the underwater effluent discharge with the receiving water. |

Lip-shaped opening of a duckbill valve under normal flow conditions |

¡@

¡@

|

This project aims to study the hydraulic characteristics of outfall diffusers fitted with duckbill valves, and the mixing of effluent discharges from these valves. Theory and experiments show that the sue of duckbill valves results in a more uniform port discharge distribution, higher jet velocities, better sea water purging, higher energy heads, and more effective near field dilution close to the source. |

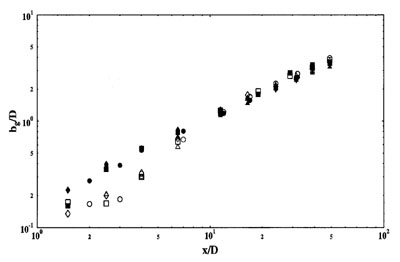

Measured velocity half-width vs. downstream in minor axis (solid symbols) and major axis (open symbols) ¡@ |

¡@

|

|

¡@

¡@ ¡@ |

||

|

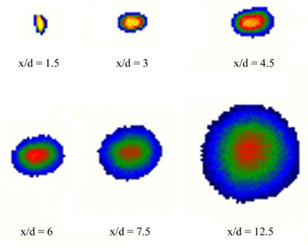

Cross-section shape of a duckbill valve jet at different location downstream; the extent of pollution is revealed by the laser-induced fluorescence (LIF) images. Note the changes from an oblong to circular shape. |

Duckbill valve installed on pillar point outfall riser (with glass reinforced plastic top) |

¡@